Diallyldimethylammonium chloride(DADMAC)

DADMAC (diallyl dimethyl ammonium chloride), full name of diallyl dimethyl ammonium chloride, is a cationic quaternary ammonium monomer.

In water treatment, DADMAC and its polymers are widely used as flocculants and flocculation AIDS, with good flocculation and removal of suspended solids, algae, organic matter and other functions.

Its application covers drinking water treatment, wastewater treatment, industrial recycling water treatment and many other aspects.

Email address :info@jinmaicn.com

Telephone :+8617753136665

-

Product Introduction

-

Product Specification

-

Product Application

-

Quality Certificate

-

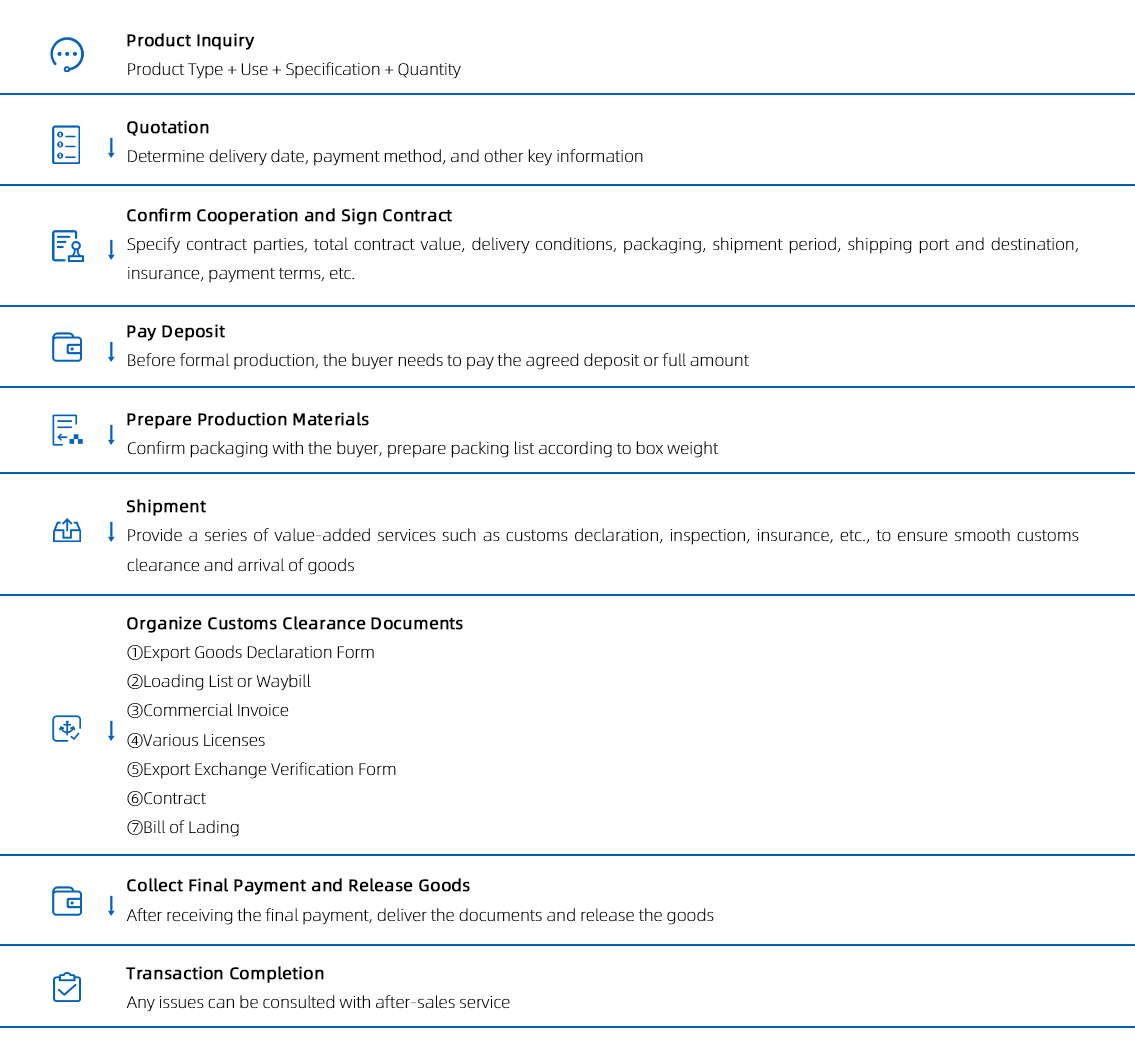

Transaction Process

-

Packaging Standards

-

Transportation Guarantee

-

Service Commitment

Regular name: DADMAC (60/65)

Molecular formula: C8H16NCl

CAS No.: 7398-69-8

DADMAC is a water-soluble monomer of highly efficient cationic quaternary ammonium salt. The molecular structure contains alkenyl double bonds, which can form linear homopolymers and various copolymers through various polymerization reactions.

| Product | DADMAC 60 | DADMAC 65 |

| Appearance | Colorless to light yellow transparent liquid | Colorless to light yellow transparent liquid |

| Solid Content | 60±0.5 | 65±2 |

| PH | 3.0-7.0 | 3.0-7.0 |

(1) In drinking water treatment, DADMAC can be used as a flocculant to help remove suspended particles and turbidity in water and improve water quality. DADMAC can effectively remove colloids and suspended substances in water and improve the clarity and transparency of water through electrical neutralization and adsorption bridging.

Wastewater treatment

(2) In the treatment of industrial and domestic wastewater, DADMAC is mainly used in the flocculation and precipitation stage, which can effectively remove suspended matter, heavy metal ions, organic matter and other pollutants in wastewater. It plays an important role in improving the precipitation efficiency, reducing the burden of subsequent biochemical treatment and improving the efficiency of wastewater treatment. Especially in the fields of dye wastewater, papermaking wastewater and oilfield recovery water treatment, DADMAC has shown good treatment effect.

Industrial recycled water treatment

(3) In industrial production processes, such as circulating water systems such as cooling water systems and boiler water, DADMAC can be used to control water quality, inhibit algae growth and deposition, and prevent corrosion and scaling in water systems. By reducing microbial activity in the system, DADMAC helps maintain a clean and efficient operation of the entire system.

Algae control

(4) DADMAC and its polymers are used as bioflocculants to control the growth of algae in some specific situations. The algae can be removed and controlled by flocculating, and the balance of water ecology can be maintained.

(1) Ensuring Safety:

The packaging materials we choose that can withstand various physical and chemical challenges encountered during long-distance transportation, including drops, pressure, and changes in temperature and humidity. For hazardous chemicals that are flammable, explosive, toxic, or corrosive, special safety packaging will be used to ensure compliance with the United Nations “Recommendations on the Transport of Dangerous Goods: Model Regulations” (also known as the UN regulations).

(2) Leakage Protection:

Our packaging will include enhanced measures to prevent leakage, especially for liquids or chemicals that can produce harmful vapors. This will be achieved through the use of double-layer packaging or special sealing techniques to provide additional safety assurance.

(3) Clear Label Information:

We will ensure that correct labeling information is clearly marked on the packaging, including product name, hazardous material identification, batch number, manufacturer information, etc. Hazardous materials will be labeled with the appropriate hazard labels and UN numbers in accordance with international regulations such as the IMDG Code (International Maritime Dangerous Goods Code) or ICAO TI (International Civil Aviation Organization Technical Instructions).

(4)Environmental Protection Factors:

Our packaging will take environmental impact into consideration. We will use recyclable or biodegradable materials as much as possible, avoid excessive packaging, reduce waste and costs, and adhere to the principles of sustainable development.

(1) We will ensure the transportation vehicles and related equipment are in perfect condition and meet all safety standards and regulatory requirements.

(2) We will ensure that the speed, route, and driving safety during transportation comply with traffic regulations and customer requirements, avoiding illegal and dangerous driving.

(3) We will ensure that the storage, loading, unloading, cleaning, maintenance, and repair of chemicals during transportation comply with safety regulations and requirements, maximizing the safety and stability of the chemicals.

(4) We will ensure that professional and skilled staff coordinate, operate, and manage the delivery and distribution processes, with effective emergency response and handling measures in place.

(5) We will monitor and track the entire transportation process through tracking records, video surveillance, and ensure timely response and handling of related incidents.

(6) We will adhere to relevant laws and regulations, strictly managing and controlling the transportation of chemicals to ensure their safety.

(1) We will provide timely transportation and delivery according to customer needs, ensuring prompt fulfillment of customer delivery requirements.

(2) We will adhere to transportation schedules, achieving precise delivery, improving delivery efficiency, and offering comprehensive delivery services.

(3) We will establish a complete customer service system, equipped with a professional chemical management team, to ensure delivery times and promptly deal with customer complaints, inquiries, and other issues.